Mixers produce compressed ready-mixed concrete by primarily mixing aggregates, admixtures and cement, although their capacity and ease of use vary.

Mixers to be used in concrete plants have three main criteria: capacity, level of homogeneity of the mixture over a given time and the area that the mixer will cover inside the power plant, preferably by calculation.

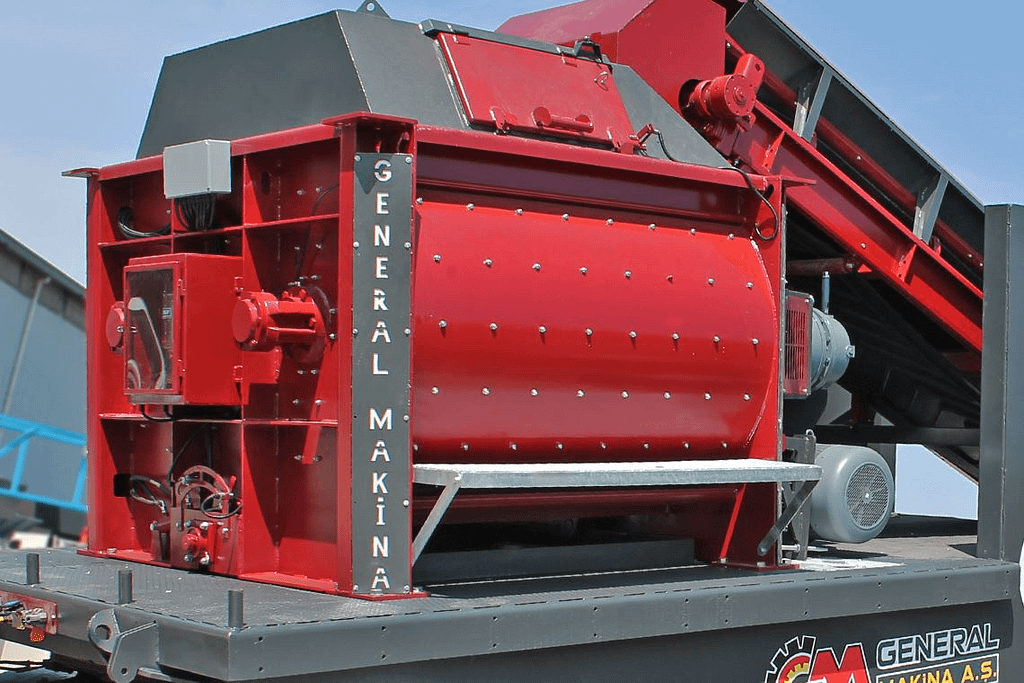

The types of mixers we produce as a general machine are sorted as tray type mixer, single shaft (single spindle mixer) and double shaft (dual spindle mixer).

They can consistently provide the desired full output in stationary concrete batching plants or in special concrete preparation projects.

GENERAL MAKINA concrete mixers with low investment costs, from 0.5 m3 to 4.5 m3, in addition they can produce ready-mixed concrete with special decomposition power.

The ready-mixed concrete produced has a high compression rate and can be discharged using a hydraulic or pneumatic single or double cap system.

During power interruptions, the mixture outlet caps inside the mixer can be opened manually.

Our faucets have internal liners coated with wear-resistant Ni-Hard, while replacement of these liners is possible using a bolt-on system. The molding type of the liner can be selected according to customer demand.

Mixer handles and side inserts are coated with Hardox.

The durability of the faucets body is quite strong as it is made of steel structure. They also have an extra layer of paint to protect them from surrounding climate-induced corrosion.

In pot mixers;The rotor and its arms have a feedback system to absorb pressure from sudden pinching. The bearing section of the drive shaft does not come into contact with the concrete, so there will be no leakage or bearing issues in the future.

In double-spindle mixers;Dual side drive mixer arms keep the unit continuously centered and reduce overall wear and tear costs, plus our company uses Ni-Hard in the structure of the arms and scraper trays here for maximum strength.

Single shaft mixers have high capacity and operating costs are at an appropriate level. The most important advantage is the use of the optional dual drive system. The dual drive ensures maximum uniformity, capacity and failures that may occur in one of the drive groups, allowing production to continue without decadence.

All faucets have a walking platform for maintenance and intervention. Our concrete mixers also have a system that can carry out automatic lubrication from different points, and a cleaning unit can also be added as desired.

All our faucets are manufactured to ISO 9001 and CE quality standards.

They have a 1-year warranty and 10-year parts support, excluding user error and wear parts.

You can contact us to buy concrete mixer with our reasonable prices

Specifications

| TYPE | PAN TYPE MIXER | SINGLE SHAFT | TWIN SHAFT | |||||||

| MODEL AND FEATURES | GNR-0.5M3 | GNR-1M3 | GNR-2M3 | GNR-0.5M3 | GNR-1M3 | GNR-2M3 | GNR-1M3 | GNR-2M3 | GNR-3M3 | GNR-4.5M3 |

| Compacted Concrete (m3) | 1 | 1 | 2 | 1 | 1 | 2 | 1 | 2 | 3 | 4.5 |

| Dry Volume (m3) | 1.5 | 1.5 | 3 | 1.5 | 1.5 | 3 | 1.5 | 3 | 4.5 | 6 |

| Motor Power (kW) | 30 | 37 | 45 | 18 | 37 | 2×37 | 2×18.5 | 2×45 | 2×55 | 2×90 |

| Reduction Gear | Planet | Planet | Planet | Planet | Planet | Planet | Dkp dissan planet | Dkp dissan planet | Dkp dissan planet | Dkp dissan planet |

| Body Wear Plates | 12 mm st52 | 12 mm st52 | 15 mm st52 | 12 mm st52 | 12 mm st52 | 15 mm st52 | 20 mm st52 | 20 mm st52 | 20 mm st52 | 20 mm st52 |

| Mixer and Scraper Pallets | Hardox | Hardox | Hardox | Hardox | Hardox | Hardox | Hardox | Hardox | Hardox | Hardox |

| Sole Wear Plates | Hardox | Hardox | Hardox | Hardox | Hardox | Hardox | Ni-Hard | Ni-Hard | Ni-Hard | Ni-Hard |

| Hydraulic Discharge Cover | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| Safety Equipments | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |