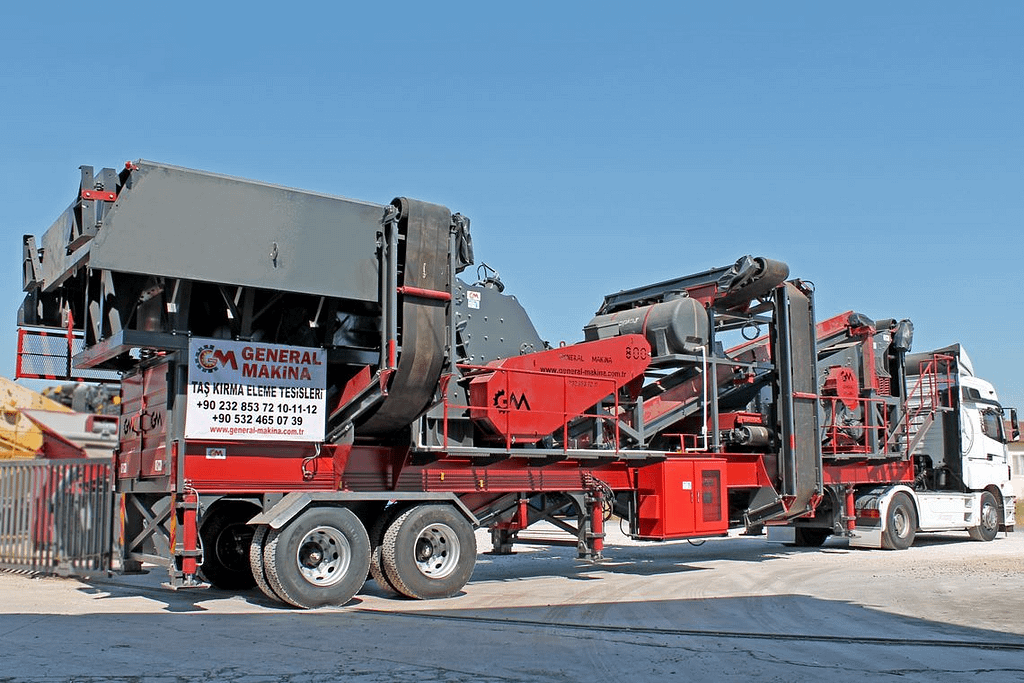

The General 800 mobile crushing and screening plant is a closed loop crushing and screening plant with high shrinkage and cubic material. The General 800 stone crushing plant has a unique design and application, it is capable of crushing, not to mention stone, stones over a large area, from January to stream beds, and has sorting capabilities. It has a closed operating system to produce precisely proportional cubic products and desired capacities.

Portability and ease of installation in crushing and screening plants was a major concern for time-sensitive customers. In accordance with our clients’ wishes, we have made most of our spaces portable in one unit, resulting in a portable design. Thus, the time spent on installation and installation was reduced to a minimum. All General 800 equipment runs synchronously on one chassis, eliminating additional costs for our customers

To further reduce setup and teardown times, we have added hydraulic mounts as standard lifting mounts for quick installation (optional hydraulic folding belts, vibrating screen tilt, feeder hopper covers and folding folding walkways) on all of our mobile units, as well as for eliminating the tasks of fastening, digging rooms, thanks to which the fixed supports are commissioned and installed. it will be completed.

The General 800 mobile crushing and screening plant has a capacity of 80 to 120 december/hour.

It comes with a 1-year warranty and 10 years of paid service support, excluding wear parts.

All General Makina products are CE certified by the European Union as well as ISO 9001.

Feeding system

Thanks to the new design adapted for mobile systems, installation and use are quite simple. Additionally, it shares the same signature design as stationary feeders to withstand harsh construction site conditions. With the help of a bypass grid, the Tween is able to separate the soil inside. It is used to feed all mineral stone materials of different hardness and recycling materials into the crusher.

- Installation of side covers can be chosen as classic hinged or hydraulic.

- Body armor is wear-resistant and interchangeable.

- Heavy-duty springs adapted to the mobile system.

- The drive system can be made using single or dual vibration motors.

- The material feed speed is controlled by a vibration drive control system.

- Automatic lubrication system can be selected for ease of maintenance.

- Easy screening with one and two stage bypass screen

Crushing system

From the outset, a redesigned mobile crusher with a focus on minimum costs for maximum efficiency, delivering plant power.

At the same time, the nature of the installation is determined by the different types of mobile crushers.

The mobile primary impact crusher has adapted to a portable design without sacrificing capacity.

Stone of any hardness – destroys rocks and minerals. Wear life varies accordingly.

This crusher we produce according to our more than 45 years of experience, in general,

- Both primary and secondary crushing process in one crusher.

- You can choose a classic double or triple system – internal fenders of the GPS series.

- Has a high degree of shrinkage.

- With a soft starter preference, you can switch to low power consumption.

- It features a reinforced housing design that provides the highest level of crusher integrity.

- The hull armor liners and main rotor beaters are interchangeable.

- Checking the final product can be done more conveniently with three tread adjustment units.

Vibrating Screen System

The mobile vibrating screen is designed for increased productivity and can handle even the toughest conditions. Its screening capacity is adapted to various stone and mineral materials.

The features of mobile vibrating screen are as follows,

- Works synchronously with the crusher with maximum efficiency.

- The body components are of non-welded bolted construction.

- The sieve wire is steel and imported, it is easy to replace.

- The drive system can be selected using vibration motors or a classic camshaft drive.

- The inclination of the sieve can be further adjusted using a hydraulic system.

- Compatible with all general purpose screening plants.

Conveyor system

Mobile conveyor belts are ideally adapted to portable installations. They are made from high quality belt rubber with a reinforced chassis and bolt-on design and durable rollers. These conveyors have technological advantages such as automatic installation and frequency control.

The main advantages of mobile conveyor belts are as follows,

- Installation or assembly in transport position is completed in 15 minutes.

- The drive system is driven by a gear motor, and a frequency system can be added.

- Top closure, dust removal unit can be added.

- The material unloading areas and rolls are covered with rubber.

- An automatic lubrication and rotation counting system can be added.

- A magnetic protection system can be added.

Mobile chassis system

A mobile chassis gives a name to a facility by moving all the equipment on it.

The mobile chassis, a product of General Makina, is compatible with all construction equipment tractors.

The main advantages of the mobile chassis system:

- Unlike stationary crushing and screening plants, it transports the entire plant on one platform, so it can be safely used in multiple projects.

- Highways are sized and signalized (traffic lights) in accordance with traffic regulations.

- It has a standard two-axle wheel system, the length of the chassis and the number of wheel axles increase depending on the weight of the object it will carry.

- The chassis structure is made of black steel grade A1. The connection areas are reinforced through additional welding.

- Has a pneumatic brake control system.

- Installation can be completed in 15 minutes using the hydraulic foot system.

Control panel system

The mobile control panel is the central node of the facility, which monitors and manages all processes at the facility. The performance of plant equipment and installations can be checked and controlled using a mobile control panel.

General features of the mobile control panel:

- Suitable for use with standard mains or generator power.

- Can work with 50 Hz and 60 Hz frequency converters.

- It is possible to add an emergency stop system and sound and light warnings in critical situations.

- Energy savings can be achieved in crushers by using the Smart Soft Start system as an option.

- With the optional frequency control unit, the speed of the feeder, conveyor belts and vibrating screen can be optimized.

- Controlling the facility is quite simple using a touch screen control system.

- You can add remote control or an Internet connection monitoring system.

- The outer casing of the panel is waterproof and dustproof, and the control covers have locks.

Specifications

| Transport Dimensions (WxLxH) | Weight (kg) | Capacity (t/h) | ||

|---|---|---|---|---|

| W | L | H | ||

| 3800 | 15000 | 4500 | 35000 | 80~120 |