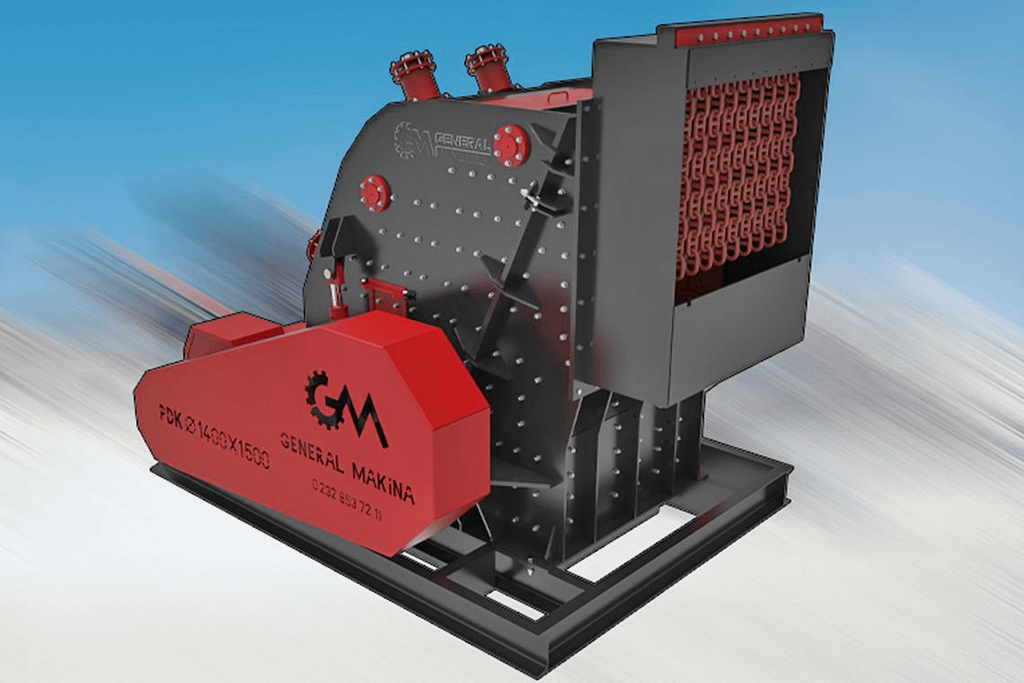

A series of impact crushers are designed for crushing soft rocks such as limestone, dolomite, gypsum, rock salt, etc. The scrap pallets of this equipment are easy to install and, if necessary, can be easily replaced. In addition, this equipment can be used for processing both primary and secondary raw materials, since the hydraulic system built into the equipment allows you to quickly and easily adjust the size of the feeder intake, thereby adjusting the productivity and size of the final raw material of the equipment. The equipment has a high degree of grinding. 75% of the raw material is crushed to a size of 0-55 mm. Depending on the user’s wishes, the equipment is made of manganese or chromium, which protects it from rapid wear. Crushers are easy to mobilize.

Features of Primary Impact Crusher:

- High performance,

- High grinding ratio,

- High productivity of thin material,

- The final raw material is cube-shaped,

- Easy to maintain.

This equipment is designed for grinding stones of medium hardness. Primary impact crushers can crush stone weighing 3000 kg, volume 1300 mm to size 0-100 mm.

Specifications

| Model | Rotor size (mm) | Maximum size of initial raw materials, mm | Productivity, t/hour | Motor power, kW |

|---|---|---|---|---|

| GNR PDK01 | 1400×1500 | 1000 | 250~500 | 315 |

| GNR PDK02 | 1400×1200 | 900 | 200~300 | 200 |

| GNR PDK03 | 1600×2000 | 1300 | 500~900 | 500 |