This type of sieve works elliptically. The elliptical rotation is carried out radially from the back to the front of the screen, then from the front to the back. In the rear part of the sieve, the rate of raw material flow is higher than in the front part. Thus, top-controlled vibrating screens are more efficient than other types of vibrating screens. The productivity of vibration sieves depends to a large extent on the type and moisture content of the raw material, as well as on the washing of the raw material upon entering the sieve.

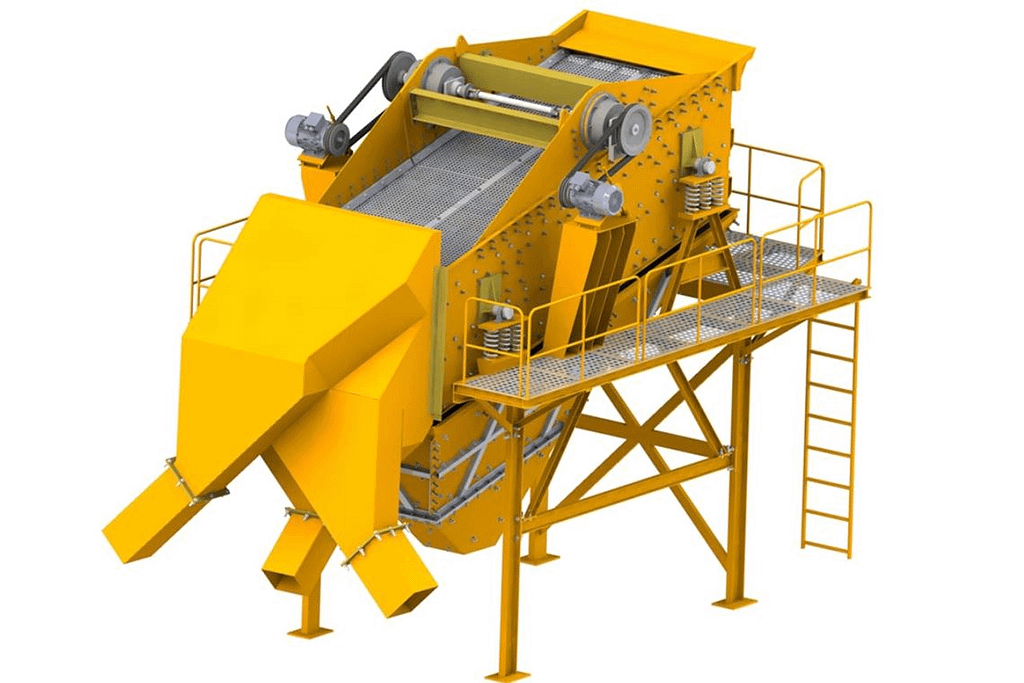

Top-controlled vibrating screens are manufactured on stationary legs or on legs bolted to a chassis. In order to carry out maintenance or change of vibrating screen grates, platforms are installed in the upper part for easy access. Each support group has 2 special bearings. Sieves with a size of less than 14 m2 have 2, and those larger than 14 m2 have 4 support groups.

Specifications

| Model | Vibrating sieve dimensions, mm | Motor power, kW*rpm | Number of layers, pcs | Weight, kg |

|---|---|---|---|---|

| ELK-U2050 | 2000×5000 | 2×15/1500 | 3 | 15000 |

| ELK-U2060 | 2000×6000 | 2×15/1500 | 3 | 17500 |

| ELK-U2460 | 2400×6000 | 2×15/1500 | 3 | 19000 |