Log washing; Sand, gravel and various ores, obtained naturally from streams and stream beds or as the final products of stone crushing and screening plants, are used in various industries in their pure form, that is, separately from each other and from foreign materials; It is cleaned of any remaining clay, silt or sediment.

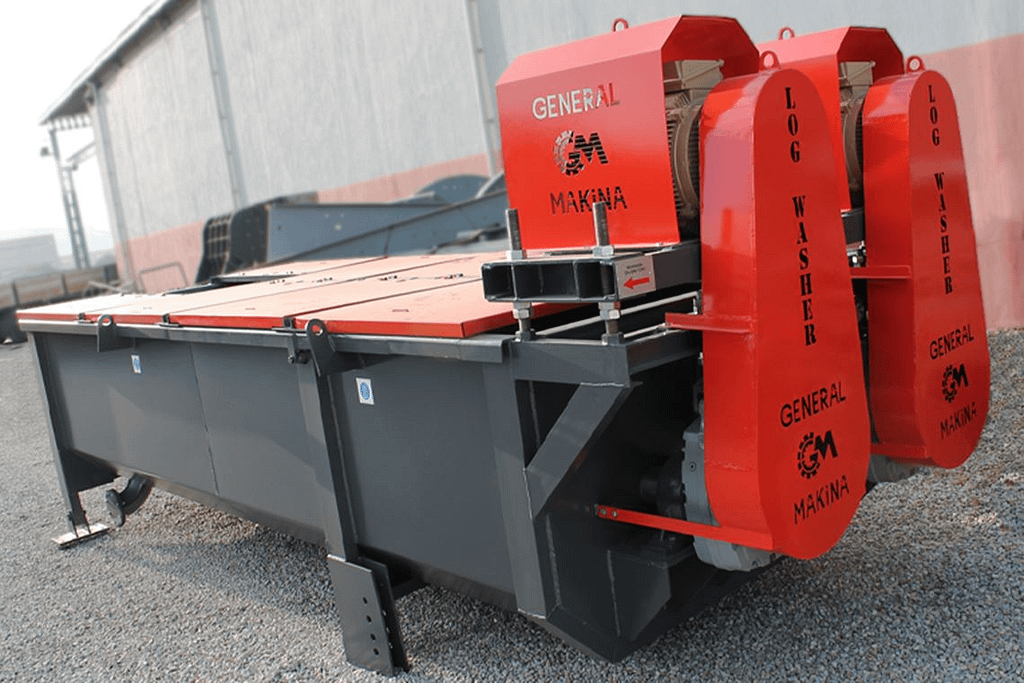

The log washer, which essentially looks like a screw washer, simply produces dirty materials and dirt due to the mechanical action on the boiler water and materials inside by wear-resistant paddle arms on two gearmotor driven log shafts located in the wash tank, rotating opposite each other with at the same speed, separates materials from each other and removes them through the discharge chute. The biggest difference that sets it apart from regular screw washers is that it can also wash larger materials or stones.

Sand, gravel and mineral ores purified in this way meet the requirements of the construction, industrial and chemical industries. In particular, the cumulative demand of concrete plants is one of the best examples of this.

Excess water in the system is discharged through drain gutters before it exceeds the level allowed by the operating angle defined in the machine installation. If desired, water consumption in the system can be minimized using an additional circulation pump.

Log washing can be made either stationary or mobile upon request. The rotor bearings are installed in such a way that they are not exposed to water. The passage points of the rotor shaft inside the washing tank are isolated from water. The log shaft shovels contain manganese alloy, and the heads attached to the arms have packing nuts and are easily replaced.

Optional:

- Frequency-controlled speed unit

- Automatic lubrication unit

- Flushing device with nozzles

- water circulation pump

- Hardox boiler coating

You can contact us for information or to make a reservation…