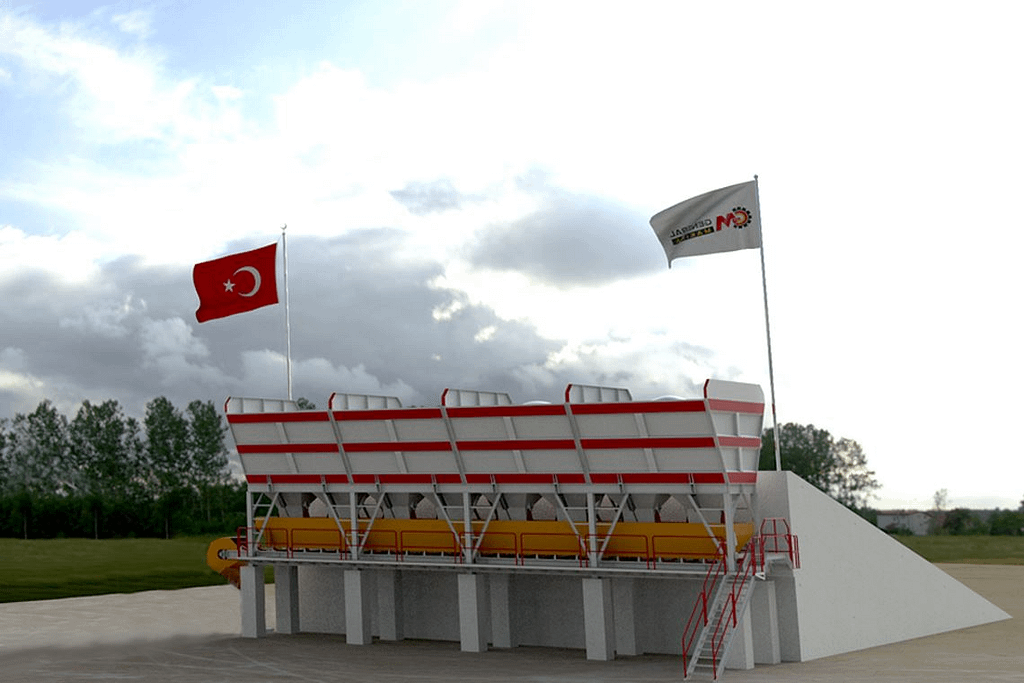

Aggregate bins used in concrete plants, in the first stage of production, store sand, crushed stone, aggregates and crushed stone or mineral materials of special sizes, regardless of external environmental conditions, and supply concrete mixers.

Generally, it is suitable for loading directly from a bucket or truck using a ramp.

Loading can also be done using a conveyor belt from my aggregate pre-feed site or one-eyed bins.

The body material is made of rolled sheet metal, the side covers are hinged, each chamber has the characteristics of a vibration motor (optional).

The hopper lids are controlled by automation and operated by a pneumatic drive. Additive scales implement intelligent material additive according to the information received from strain gauges.

The high-capacity aggregate stock from 20 m3 to 500 m3, as well as the material it stores, is manufactured with 2 grains, starting with the increasing one.

Transport characteristics comply with international delivery standards.

It has ease of installation. Provides 10 years of spare parts support and a 1 year warranty. (Parts naturally susceptible to abrasion and user error are excluded)

You can call us now for aggregate bins or complete concrete batching plant prices!..

Specifications

| Stock Compartments | Stock Compartments Capacity ( m3) | Weighing Belt ( mm ) |

| 2 | 15 | – |

| 3 | 25 | – |

| 4 | 15 | 800×12000 |

| 25 | 1000×13000 | |

| 30 | 1000×14000 | |

| 30 | 1000×14600 | |

| 5 | 35 | – |

| 6 | – | – |

| 7 | – | – |

| 8 | – | – |