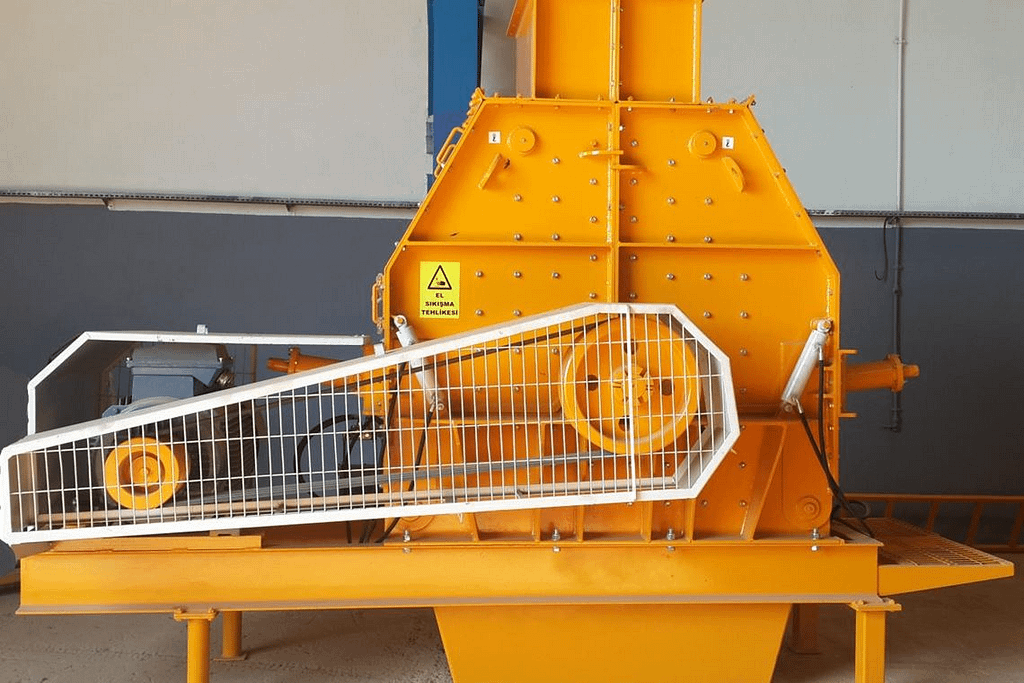

Tertiary crushers are used to produce fine cube-shaped raw materials. The crushing process is carried out by hitting stones on stationary pallets while the rotor rotates.

Features and advantages of tertiary crushers:

Both crusher covers can be opened, thereby facilitating the maintenance of the device.

These crushers produce raw materials suitable for concrete and asphalt plants. Ideal for crushing stones left on top of the sieve. The maximum size of the initial raw material: for sea stone 80 mm, for mountain stone -150 mm.

Due to the ability to rotate the rotor in both directions, the hammers are also double-sided.

Thanks to the special design of the pads and the rapid rotation of the rotor, it is possible to obtain raw materials in the form of sand.

Specifications

| Model | Rotor Size(mm) | Maximum Feed Size (mm) | Capacity(t/h) | Motor(kW) |

|---|---|---|---|---|

| GNR 65 | 1200×650 | 150 | 70~130 | 132 |

| GNR 100 | 1200×1000 | 150 | 90~160 | 160 |

| GNR 130 | 1200×1300 | 150 | 130~200 | 200 |

| GNR 150 | 1200×1500 | 150 | 200~300 | 250 |