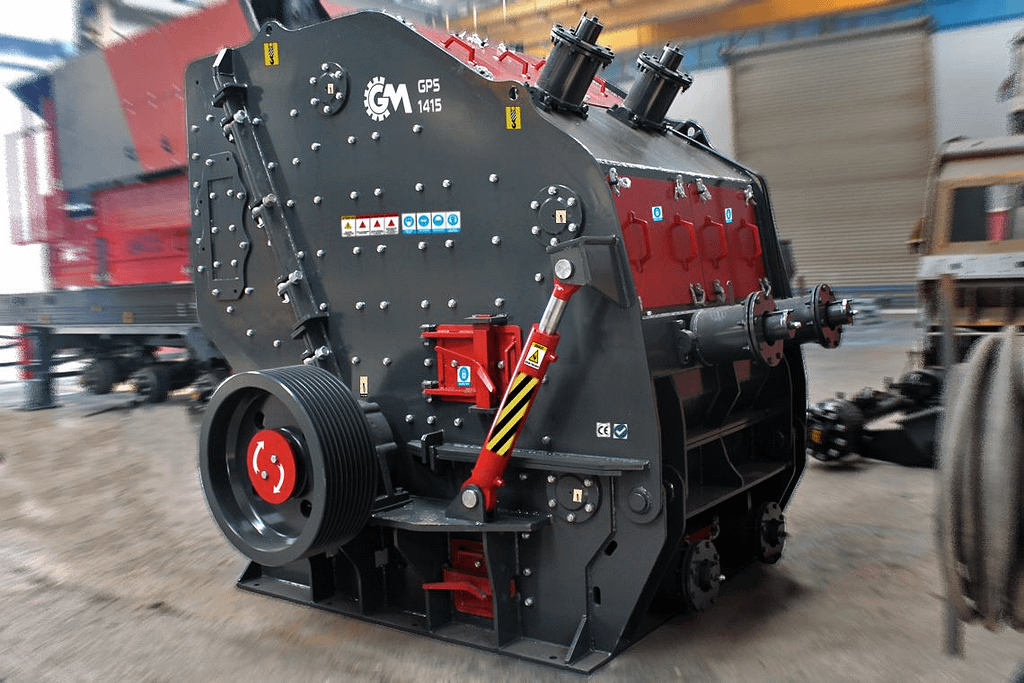

The GPS series is the latest series of professional rock crushers that General Makina has developed over the years.

The main element that gives the GPS General Primary Secondary series its name and distinguishes it from the classic impact crusher is the triple pendulum system, which allows it to perform primary and secondary crushing functions in one crusher. This crusher was created using the latest technology from General Makina, which has dominated the stone crushing industry for 50 years.

The GPS series impact crusher is especially relevant when you want to increase the productivity of your stone crushing and screening plants or when you want to increase the ratio of fine material, the 3rd pendulum unit is moved back to increase productivity with a unique triple pendulum. system.

To increase the thin material ratio, the 3rd pendulum block is moved forward. The process is so simple that there is no need for an additional crusher or return belt.

It can be used on all stationary, mobile or semi-mobile crushing and screening plants.

It crushes non-abrasive medium to soft stones and mineral materials with high efficiency.

In addition to classic work on the construction of roads and dams, it is used in a wide range of stone crushing operations, including mobile processing plants.

GPS series impact crushers are offered with a 2-year warranty excluding wearing parts, 24-hour domestic service and a maximum of 48-hour overseas service.

You can immediately contact our professional sales team to find out the price of GPS impact crusher for sale or other impact crusher.

Peculiarities

- Fast and safe maintenance and replacement of parts thanks to the hydraulic body opening system.

- Primary and secondary crushing in one crusher.

- Outstanding academic performance in elementary or high school.

- Best in class with triple pendulum system

- High contraction speed

- Low power consumption

- Improved chassis components for added durability

Standard Features

- High performance

- High productivity of thin material

- Cubic product

- Easy to maintain

- Hull and blade armor made of manganese alloy

- Replaceable body armor

- Rotary beaters suitable for double-sided use

Additional features

- Overheat sensor

- Mobile crane for changing rotor and tray

- Automatic lubrication unit

Specifications

| Model | Rotor Size Ø ( mm ) | Feeding Size ( mm ) | Motor ( kW ) | Capacity ( t/h ) |

| GPS-1210 | 1200 x 1000 | 600 | 160 | 100 – 250 |

| GPS-1413 | 1400 x 1250 | 800 | 250 | 125 – 320 |

| GPS-1415 | 1400 x 1500 | 1000 | 315 | 150 – 400 |